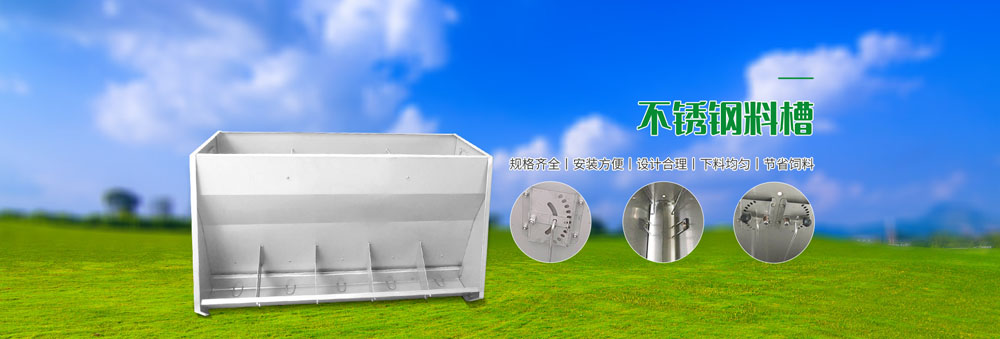

1、飼料攪拌機http://www.trilink-logistics.com/液壓油箱下的油管箍緊問題,個別廠家為了節省成本,使用普通鋼絲擰上就算完工,那樣肯定是不行的。時間長了就會松動,漏油是自然而然的事情。我們采用專業的加固圈,螺絲加緊固定,比較牢固,所以我們的設備在這個部位不容易漏油。

The problem of oil pipe hoop feed mixer hydraulic tank under, individual manufacturers in order to save costs, the use of ordinary steel wire screw on even if completed, it is certainly not. A long time will loose, oil spill is come very naturally things. We use reinforcement ring professional, screw fixed tightly, firmly, so our equipment is not easy in this part of the oil spill.

2、飼料攪拌機支路油管部分漏油,個別廠家為了省事,采用鐵管焊接而成,這樣增加了油路的接觸點,漏油概率大大增加,而是鐵管容易被腐蝕,用個一年半年就不行了。我們不惜成本采用全液壓軟管連接,減少了油路接觸點,此外專業液壓管更加耐高壓,耐腐蝕,所以也就更耐用了。

Feed mixer branch pipe part of the oil spill, individual manufacturers in order to save trouble, using iron pipe welded together, so as to increase the contact point circuit, leakage probability increases greatly, but the iron pipe is easily corroded, with a half a year is not good. We spare no cost adopts full hydraulic hose connection, reduce the oil contact point, in addition to professional hydraulic tube more high pressure resistance, corrosion resistance, so it is more durable.

3、飼料攪拌機http://www.trilink-logistics.com/液壓缸部分漏油,個別廠家為了節省成本,采用劣質液壓缸,密封不嚴,使用次數多了就會漏油,我們采用高密封液壓缸,多次抽拉液壓缸密封也會很好的。

Feed mixer hydraulic cylinder part of the oil spill, individual manufacturers in order to save costs, the use of inferior hydraulic cylinder, the seal is not strict, is used by multiple times will spill, we adopt high sealing hydraulic cylinder, repeatedly pull hydraulic cylinder seal will be very good.