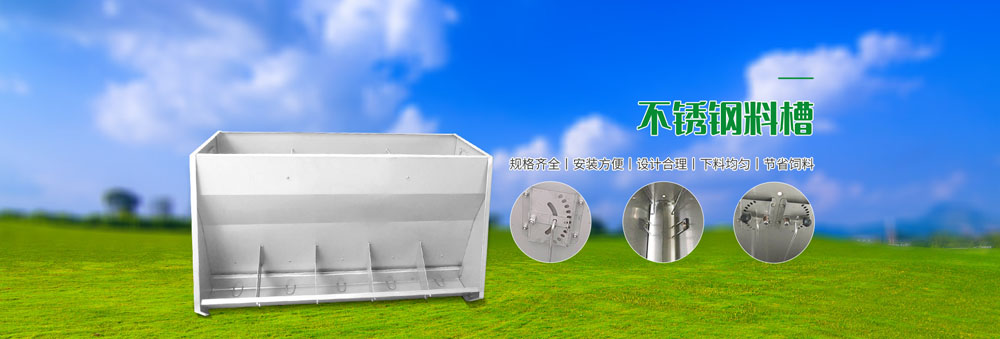

飼料混合機http://www.trilink-logistics.com/是畜牧養殖業的理想設備,是做好飼料的關鍵,對于飼料熟化、增加營養、提高吸收率、殺滅病菌、貯存運輸、降低成本、節約資源、適應動物的咀嚼功能、提高畜牧養殖效益具有重要意義。

1、飼料混合機能使混合粉料中的淀粉糊化,這樣使壓制成的顆粒飼料具有一定的香味,增加了飼料的適口性,能刺激食欲,可有效防止因挑食而造成攝入營養不均衡的現象。

Mixer makes mixing gelatinized starch powder, so make pressed into pellets with a certain flavor, increases the palatability of feed, can stimulate the appetite, which can effectively prevent picky caused by the intake of nutritional imbalance.

2、提高了飼料的消化率,可促進口腔多分泌淀粉酶,使吃到口中的飼料充分和唾液混合,刺激腸道的蠕動,大大提高了飼料中營養物質的消化率。

Improving the digestibility of feed, can promote oral multi-amylase secretion, so eat the mouth and saliva mixed fodder fully stimulate intestinal peristalsis, greatly improving the digestibility of feed nutrients.

3、飼料混合機在壓制過程中,經過短時高溫、高壓的綜合作用,不僅使飼料中的淀粉糊化、蛋白質組織化,而且使酶活性增強,使飼料中含有的豆類及谷田中的一些阻礙營養物質消化利用的物質鈍化,這些都提高了飼料的消化率,有利于胃腸的消化吸收。

Mixer in the pressing process, after short-term high temperature, the combined effects of high pressure, not only feed gelatinized starch, protein organization, but also the activity increased, so that a number of obstacles in feed containing legumes and cereal Tanaka substance use passive digestion of nutrients, which are to improve the digestibility of the feed, help digestion and absorption of gastrointestinal.

4、飼料混合機http://www.trilink-logistics.com/能殺菌消毒、減少疾病,顆粒飼料在壓制過程中,經過高達70℃-100℃的短時高溫,可殺死一部分寄生蟲卵和病原微生物。Mixer can disinfection, reducing disease, pellets in the pressing process, after up to 70 ℃ -100 ℃ high

temperature short-time, part of the parasite eggs and can kill pathogenic microorganisms.