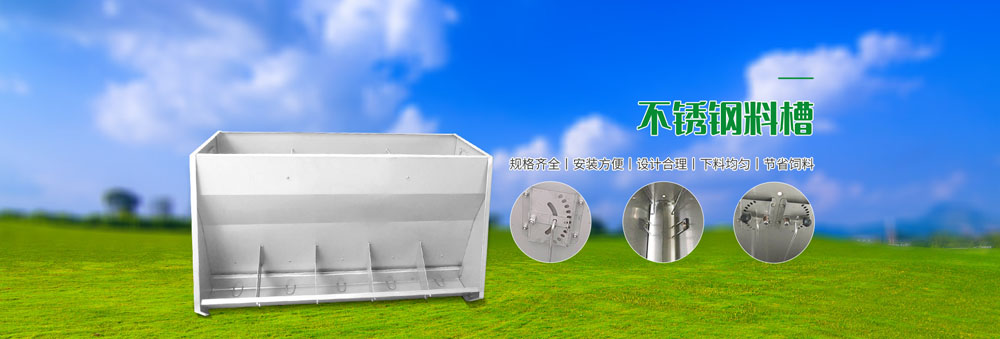

在生產飼料的過程中,飼料混合機是必不可少的一種飼料加工設備。在制粒之前,飼料混合機設備將即將制成顆粒的飼料原料充分的混合均勻以后,才能保證最終生產出的顆粒飼料營養物質是全面的,使用飼料的動物才能長的更快更好。臥式飼料混合機是在飼料生產的過程中最常用的混合機設備之一。那么,在用該混合機混合物料時,有哪些需要注意呢?

1、物料的投放一般是從混合機被啟動之后開始的,物料的投放量不要超過機器的載重,否則的不僅物料不能很好的混合均勻,如果投放量太大的話,混合機的電機可能會因無法滿足太大的動力而被燒壞。

Usually the material is put in the mixer was then started from the beginning, the material should not exceed the amount of running the machine load, otherwise the material is not only well mixed, put the amount is too large if, due to the mixer motor may not meet much power being burned.

2、用戶在使用該臥式飼料混合機進行混合物料時,物料被投放的次序也是非常重要的。一般情況小,大的物料首先被投放,小的物料可以稍后被投放。在使用該混合機混合預混料時,最好直接人工投放物料而不要使用輸送機設備,因為輸送設備在輸送的過程中可能會殘留部分的物料,從而造成預混料的離析。

Users in the use of the horizontal feed mixer and mixed material, the material is put in order is very important. Generally small, the material was first put big and small materials can be put later. When using the mixer premix, the best delivery of materials, direct labor instead of conveyor equipment, transportation equipment during transportation because of the residual portion of the material may be, resulting premix segregation.

3、該類型的飼料混合機的每批次的混合時間大約5-7分鐘,無論是粉狀飼料或是顆粒狀的飼料都可以用它來混合。不同型號的該混合機的每批次混合物料的產量是不一樣的,為了保證混合機可以均勻快速的混合物料,一定根據產量的大小選擇合適的機型。

Mixing time per batch of the type of feed mixer is about 5-7 minutes, either granular or powdered feed can be used to feed mix. Different types of output per batch mixer mixing the materials is not the same, in order to ensure that the mixer can be rapidly and uniformly mixed material must select the appropriate output according to the size of the model.