目前市場上質(zhì)量較差的飼料混合機都存在哪些問題呢?下面濟南祥富飼料機械的有關(guān)專家給大家解讀一下。

1、工作噪聲大,是由于裝配及零部件加工質(zhì)量差而造成。

Working noise, due to poor quality of assembly and spare parts processing caused.

2、安全保護措施差,如在說明書中未明確安全操作事項,過載保護裝置、除鐵裝置、傳動防護裝置、聯(lián)動聯(lián)鎖裝置、安全警示標志等項目要求缺漏。

Poor security measures, such as safe handling instructions are not clear, overload protection devices, in addition to iron equipment, transmission guards, interlocks interlocks, warning signs and other safety items required gaps.

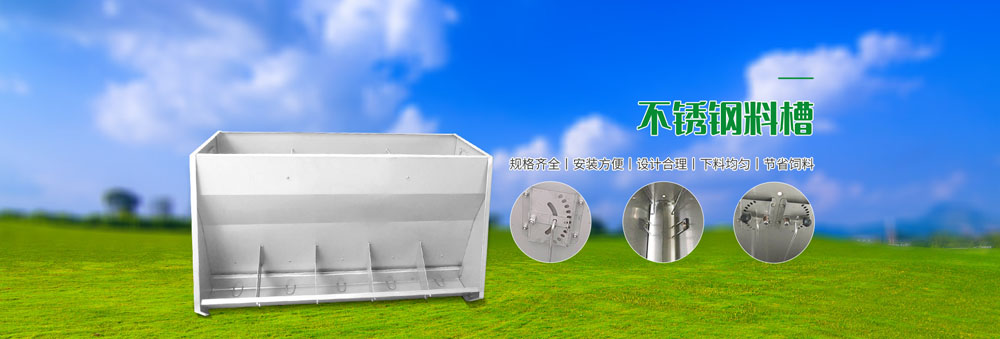

3、顆粒成形率低、水中穩(wěn)定性差,是由于模板的孔徑比不合理,飼料熟化度不合理,顆粒密度低等原因所致。

Particles forming rate, poor stability in water is due to aperture ratio template unreasonable, irrational feed ripening degree, due to the reason of low particle density.

4、模板壓輥切刀、擠壓螺桿等部件的材料選擇不合理,不做熱處理或熱處理不正確,造成這些部件的耐腐耐磨性能差,影響到設備的正常運行及顆粒飼料的外觀及內(nèi)在質(zhì)量。一般膨化混合機的螺桿壽命應在1000小時以上,小型平模壓模的壽命應在1100小時以上,環(huán)模壓模壽命應在600小時以上。

Material pressure roller cutter templates, and other parts of the extrusion screw unreasonable choice, not heat-treated or heat-treated incorrectly, causing corrosion wear of these parts is poor, affecting the normal operation of the equipment and the appearance of pellet feed and internal quality . General puffed screw mixer life should be more than 1000 hours, a small flat molding die life should be more than 1100 hours, ring mold die life should be more than 600 hours.

5、技術(shù)落后制造質(zhì)量差,造成混合機的噸料電耗項目超標,增加用戶生產(chǎn)成本。

Technology behind the manufacture of poor quality, resulting in tons of feed mixer excessive power consumption projects, increase user productivity costs.